There are 4 different basic modes to transfer weld metal (filler material) across the arc to the base material; Short Circuit, Globular Transfer, Spray Arc Transfer and Pulse Transfer. It’s crucial to select the proper mode of transfer depends on the welding process according to the suitability due to each mode of transfer has its own distinct characteristics and applications. The different transfer methods are how the weld metal from the consumable electrode is transferred to the base material over the arc.

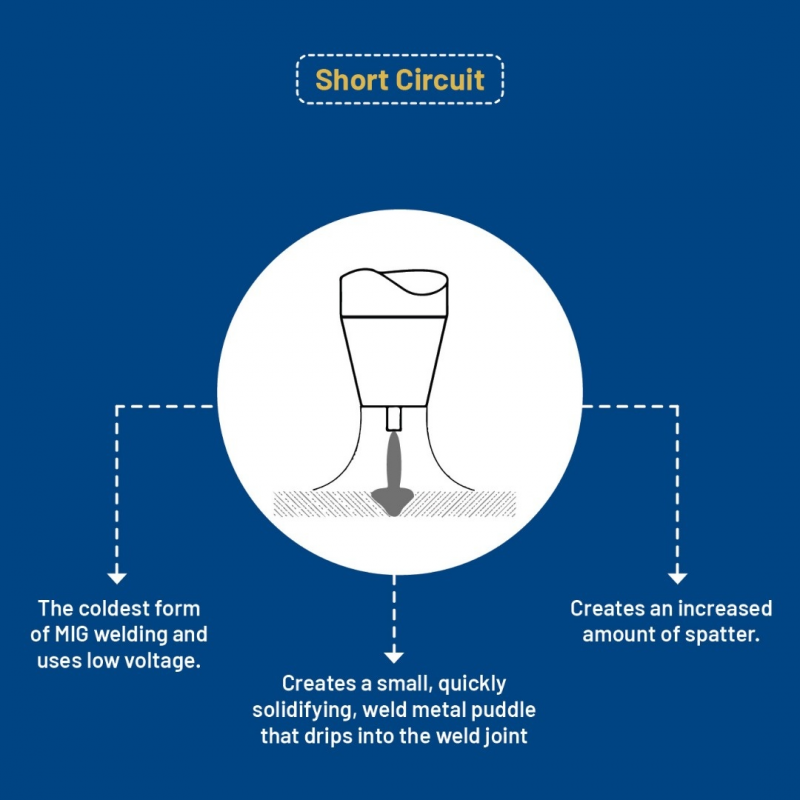

Short Circuit Transfer are the coldest form of MIG welding and uses low voltage. It creates a small, quickly solidifying, weld metal puddle that drips into the weld joint. While it creates an increased amount of spatter, this mode of transfer is versatile as it can be used in all welding positions and on all thicknesses of steel.

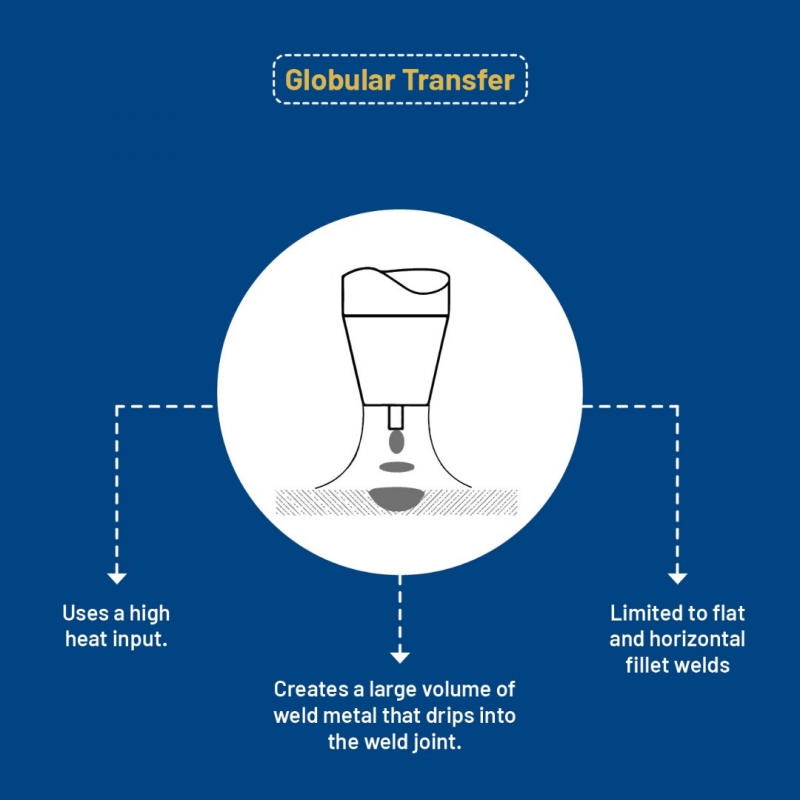

Globular Transfer is usually limited to heavier plate thicknesses. It creates a large volume of weld metal that drips into the weld joint. It uses a high heat input. Limited to flat and horizontal fillet welds.

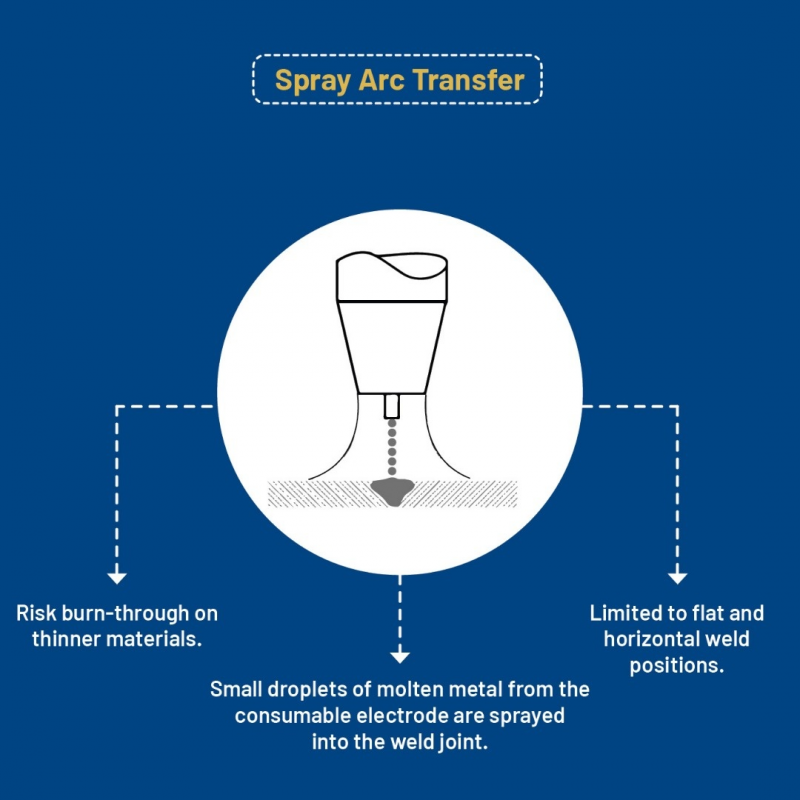

Spray Arc Transfer is small droplets of molten metal from the consumable electrode are sprayed into the weld joint. It is usually used on thicker metals and having risk burn-through on thinner materials. Limited to flat and horizontal weld positions.

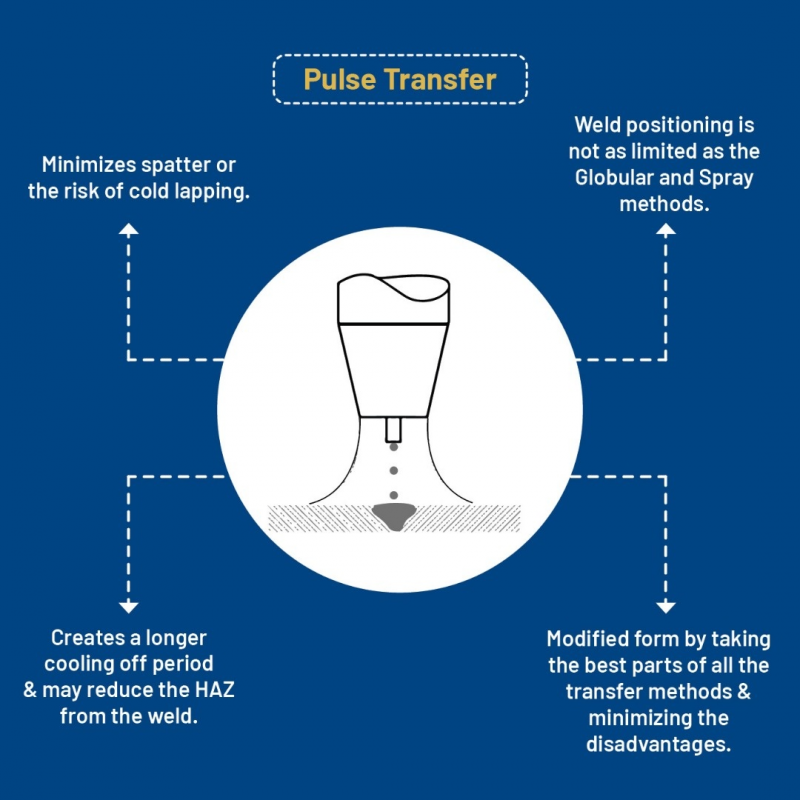

Pulse Transfer is modified form by taking the best parts of all the transfer methods & minimizing the disadvantages. It creates a longer cooling off period & may reduce the heat-affected zone (HAZ) from the weld. It minimizes spatter or the risk of cold lapping. Weld positioning is not as limited as the Globular and Spray methods. It’s versatility not only allows for welding in all positions, it’s doable on either thin or heavy plate material too.

Leave A Comment

You must be logged in to post a comment.