Regardless of your interests, needs, or you’re a Mr.DIY interested in buying your first welder. Whether you already have previous welding experience, or, you’re a welding novice, you are likely here because you need some help getting started.

There isn’t one welding process suitable for all applications, so you need to consider these factors: the type and thickness of the metal you’re welding, how big the job is, whether you’re welding indoors or outdoors, what you want the welds to look like, and your budget.

For Welding there are 3 basic elements which is Heat source, Filler Metal, Shelding gas or flux. The most broadly utilized type of welding today is electric arc welding, in which an electric arc dissolves an electrode (welding wire, for example) and partially melts the base metal. At the point when the liquid metals cool, the parts intertwine. There are distinctive sorts of arc welding, such as MIG Welding , Stick Welding , and TIG Welding .

- MIG Welding/Gas Metal Arc Welding (GMAW) — MIG welders utilize a wire welding cathode on a spool that is encouraged naturally at a steady pre-chosen speed. The curve, made by an electrical flow between the base metal and the wire, softens the wire and goes along with it with the base, delivering a high-quality weld with extraordinary appearance and little requirement for cleaning. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air.MIG welding is perfect, simple and can be utilized on thin or thicker plate metals. Mig is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation. Unlike welding processes that do not employ a shielding gas, such as shielded metal arc welding (stick welding), it is rarely used outdoors or in other areas of moving air.

Click here to view available MIG Welding Machine model at Yeowchuan Hardware.

- TIG Welding/Gas Tungsten Arc Welding (GTAW) — TIG welding is an arc welding process that utilizes a non-consumable tungsten electrode to create the weld. The weld territory is shielded from atmospheric contamination by a protecting gas (generally argon) and a filler metal, however a few welds, known as autogenous welds, don’t require it. A steady current welding power supply produces vitality that is directed over the curve through a section of profoundly ionized gas and metal vapors known as plasma. TIG welding is most ordinarily used to weld thin segments of amalgam steel, tempered steel and nonferrous metals, for example, titanium,stainless steel,aluminum, magnesium and copper compounds. The procedure gives the administrator more prominent command over the weld than other welding forms, taking into consideration solid, superb welds. It allows adjustment of heat input through hand/foot control. TIG welding is relatively more perplexing and hard to ace than different procedures and is essentially slower process that requires more skill and practice compared to other welding process.

Click here to view available TIG Welding Machine model at Yeowchuan Hardware.

- Stick Welding (Metal Arc) — If you figured out how to weld years back, you likely utilizing an arc welder. Stick welding for a long time has been the most mainstream technique for most home-shop welding needs. This procedure utilizes an electric flow spilling out of a hole between the metal and the welding stick, otherwise called an arc-welding electrode. Stick welding is a successful strategy for welding most alloys or joints and can be utilized inside and outside or in drafty zones. It’s likewise the most conservative welding strategy and gives the capacity to make an effective bond on corroded or grimy metals.

Click here to view available Stick Welding Machine model at Yeowchuan Hardware.

Notwithstanding, this strategy is restricted to metals no more slender than 18-gauge, requires frequent rod changing, produces noteworthy scatter and necessitates that welds be cleaned upon finish. Stick welding is additionally progressively hard to learn and utilize, especially the capacity to strike and keep up an arc. Arc welders are accessible in AC, DC or AC/DC, with AC being the most economical. It’s utilized for welding thicker metals of 1/16 inch or more prominent. These machines are a decent decision for ranchers, hobbyists and home support errands.

The diagram below summarizes each welding process. Consider these factors in deciding which process might be best for your general needs.

| MIG Welding

· Easiest process to learn · High welding speeds possible · Better control on thinner metals · Cleaner welds possible with no slag to clean · Great for welding indoor on variety of projects |

TIG Welding

· Provides highest quality, precise welds · Asthetically pleasing weld beads · Allows adjustment of heat input while welding by use of a foot control · Work better for thinner metal |

| Stick Welding

· Better suited for windy, outdoor conditions · More forgiving when welding on dirty or rusty metal · Works well on thicker materials · More spatter and fume welds aren’t as clean. |

|

| Metal | Welding Process | ||

| TIG | STICK | M IG | |

| Steel | √ | √ | √ |

| Stainless steel | √ | √ | √ |

| Copper | √ | ||

| Magnesium | √ | ||

| Titanium | √ | ||

| Aluminum | √ | √ | |

| Cast Iron | √ | ||

What factors would it be advisable for you to think about while deciding a budget?

You may already have an estimated budget in your mind.

The kind of welder you buy needs to be suited for the explicit capacities you require just as the tasks you will work on the most. Consider your ultimate objective and think about chances to grow the convenience of your welder. Will you need more power or amperage later on?

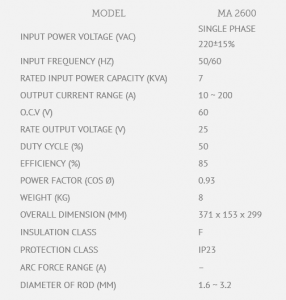

For example This is the specification of one of our MA machine model-MA2600.

First thing u may need to consider is the output current range , which for this machine it may perform from 10A – 200A. From the table it also shows that the suitable diameter of welding rod is from 1.6 -3.2 mm.

It is vital to observe the fluctuating amperage and power prerequisites just as the obligation cycle important to accomplish the best and efficient operational outcomes for the ventures you’re hoping to finish.

Notwithstanding the expense of the welder itself, remember to incorporate expenses for the extras and supplies you’ll have to work on your new welder. This incorporates welding protection gears ( welding gloves, sleeve protection , apron , helmet, and so forth.) as well as gas and consumables.

Try not to feel raced into settling on an acquiring choice at this moment. Take some time to characterize your necessities. In the event that you have questions or something is unclear, Yeowchuan Hardware can answer any inquiries you have about welding forms, advantages, confinements and machine task. When you’re prepared to coordinate an explicit model with the hobby, task or business .Yeowchuan can recommend the model or item that is the best for you.

Yeowchuan has given quality welding equipment in Malaysia since 1985. When you’re prepared to purchase, we’d be honored if your first welder was from us.

Leave A Comment

You must be logged in to post a comment.