Welding has existed for centuries and has such a long history that it’s not shocking there are some really fun and interesting facts about the welding process. Knowing the facts can help you make improvements regardless your goal is to control spatter or to increase arc-on time.

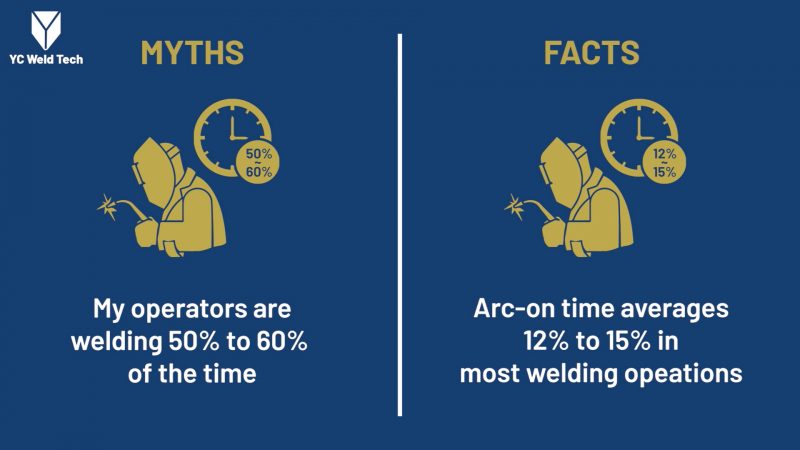

Myth: My operators are welding 50% to 60% of the time

Fact: Arc-on time averages 12% to 15% in most welding operations

It’s common for people overestimate arc-on time. Welders often spend their time on tasks that

aren’t value-added for the operation, such as grinding spatter or replacing consumables. Those

tasks shouldn’t be included when tracking arc-on time.

Grinding and chipping are part of the welding process and can’t be avoided :Myth

Using proper parameters and machine setup can greatly reduce or eliminate spatter :Fact

Do NOT think of grinding and rework as part of the welding process. Taking the time to establish

the proper weld parameters for the job can reduce or eliminate the time spent grinding and

chipping to remove spatter. To reduce spatter, train operators to use a shorter

contact-tip-to work distance.

Myth: Milk can protect against the damaging effects of breathing in poisonous welding fumes

Fact: Milk is drunk whereas fumes are inhaled, the two end up in the different parts of the body that don’t cross the path to affect each other

Milk has absolutely no effect on the consequences of welding fumes. Best solution is to have an

effective welding fume extraction system / equipment. Alternatively provide good air circulation

at open space for welding site would helps too.

Wearing contact lenses during a weld can cause the lenses to melt and fuse onto your eyes :Myth

This has been proven to be scientifically impossible. Long before contact lenses could melt :Fact onto your eyes, your skin and hair would have already started to burn

It is perfectly safe to wear contact lenses whilst welding, and it’s impossible for contact lenses to

become “welded” to the cornea. Contact lenses are sterilized with steam at around 120 degrees

Celsius, they are also boiled to clean them so they don’t melt from boiling water either. However

it is worth noting that contact lenses are not designed to be safety devises and should not be

worn as such, all normally precautions like wearing appropriate safety equipment while welding,

regardless of whether you’re wearing contacts.

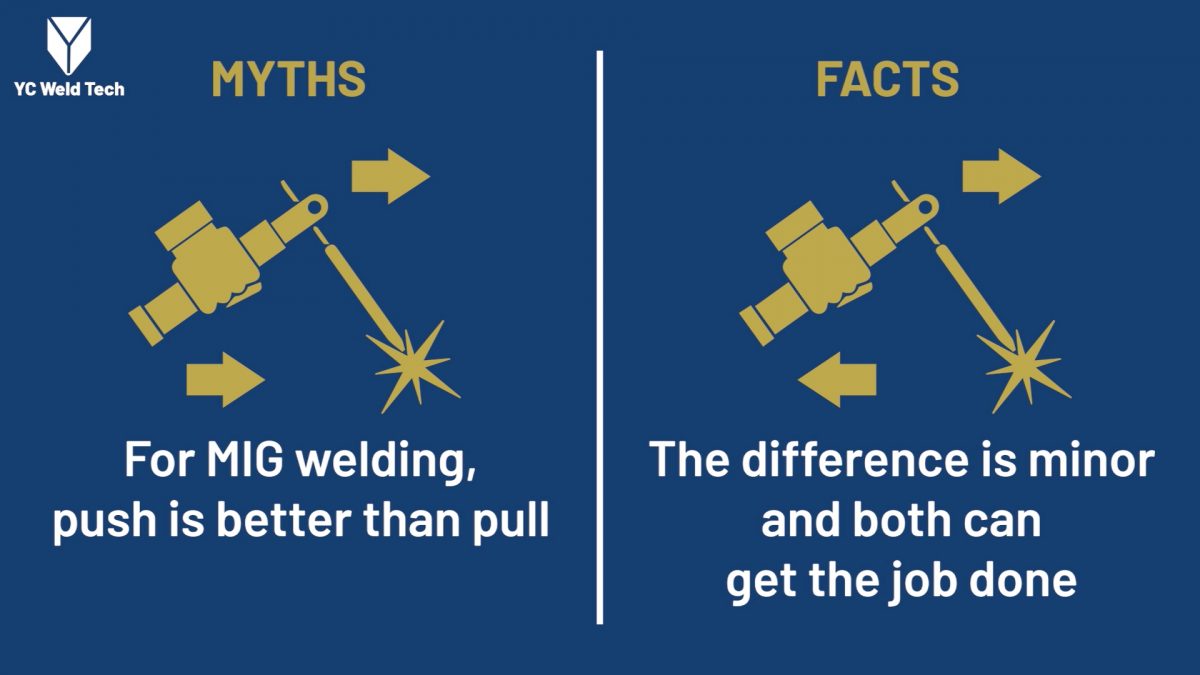

Myth: For MIG Welding, push is better than pull

Fact: The difference is minor and both can get the job done

Pulling might create a deeper penetration while pushing creates a flatter weld that covers more surface area. When you’re pushing a weld, you have the key benefit of seeing where you’re going. Most welders want to know what the weld bead looks like after a pass, and in that case pulling a weld is ideal. Pulling a weld is often ideal for welding steel, but your direction depend on a particular approach.

Is the V-groove on nuts just for decoration purposes? :Myth

Nuts with V-groove is called left-handed nuts and have left-handed thread, meaning it needs :Fact to be screwed/unscrewed in opposite direction of normal nuts

This type of nuts are commonly used in gas storage or oxyfuel cutting or welding torch, which

has two adjacent screws for oxygen and acetylene.

Leave A Comment

You must be logged in to post a comment.