Welding is an interesting yet fantastic skill to learn. Whether you’re a hobbyist working on DIY home projects or looking for a professional skill that will never go out of fashion, it is a great plan to learn to weld. There are 5 basic types of welding joints. Different types of weld are required depending on the type of job a welder is carrying out. And each joint has a specific purpose to help you get the most strength for each weld you make, depending on the forces of each individual application.

Let’s check out what are the 5 Basic Types of Welding Joints

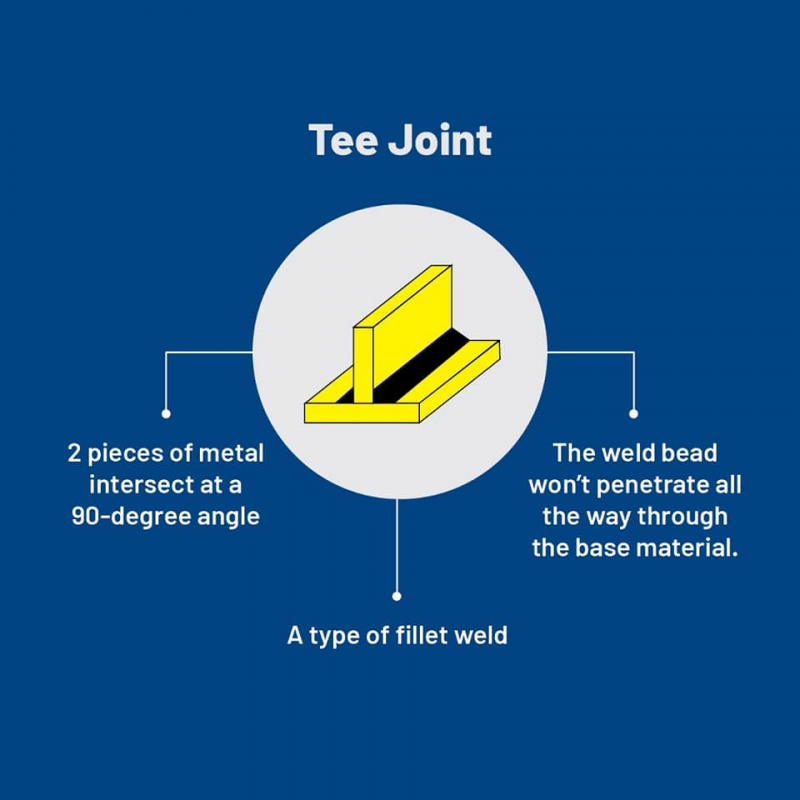

Tee Joint weld is formed when two (2) pieces of metal intersect at a 90-degree angle. It is commonly known and considered a type of fillet weld. The weld bead won’t penetrate all the way through the base material.

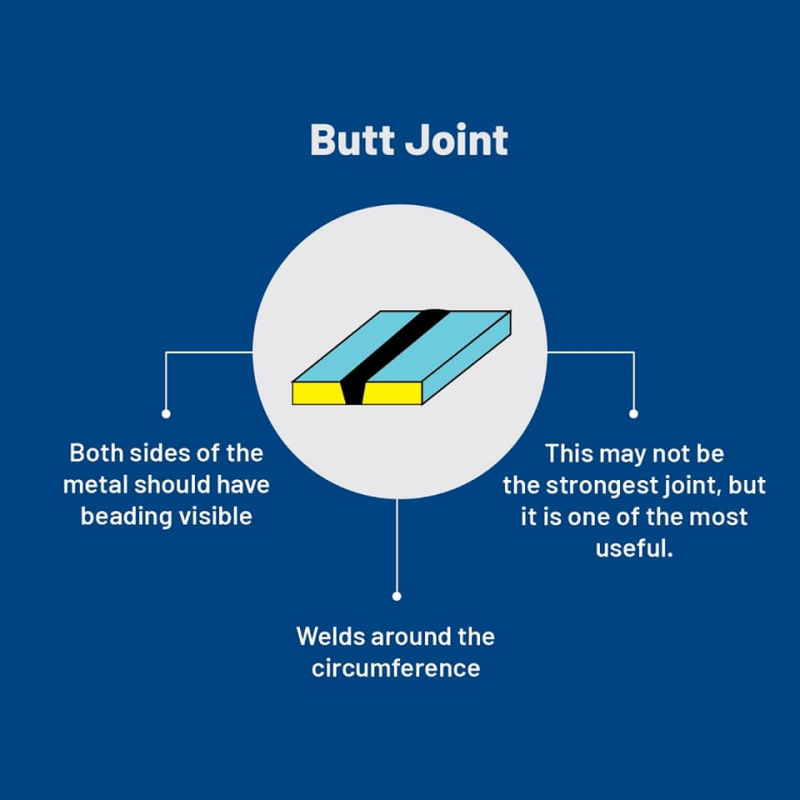

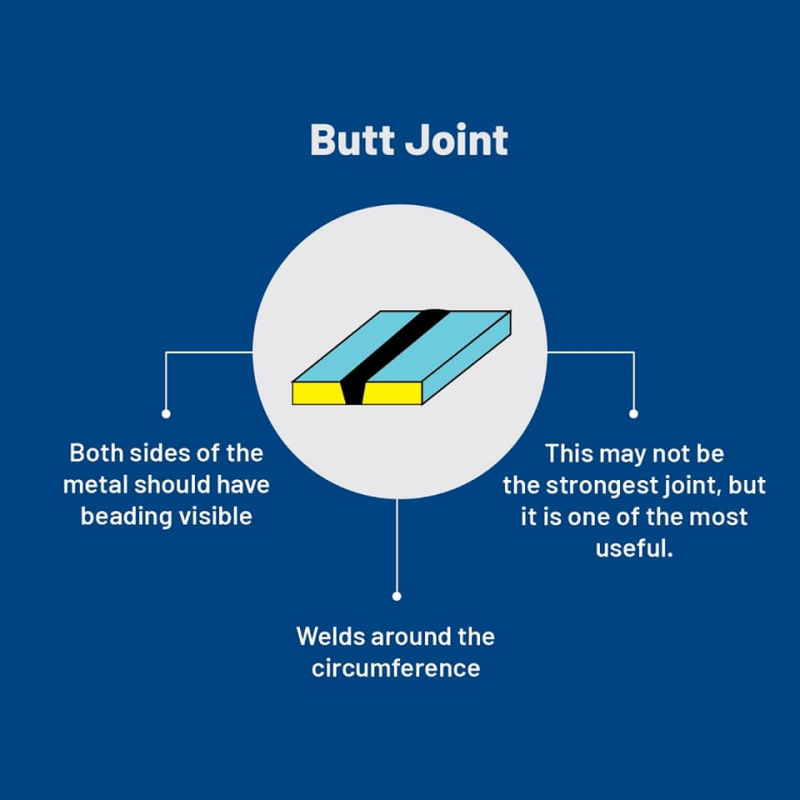

Butt Joint weld also known as the square-groove, one of the easiest to master with the right practice. It welds around the circumference as both sides of the metal should have beading visible. This may not be the strongest joint, but it is one of the most useful and most universally used method.

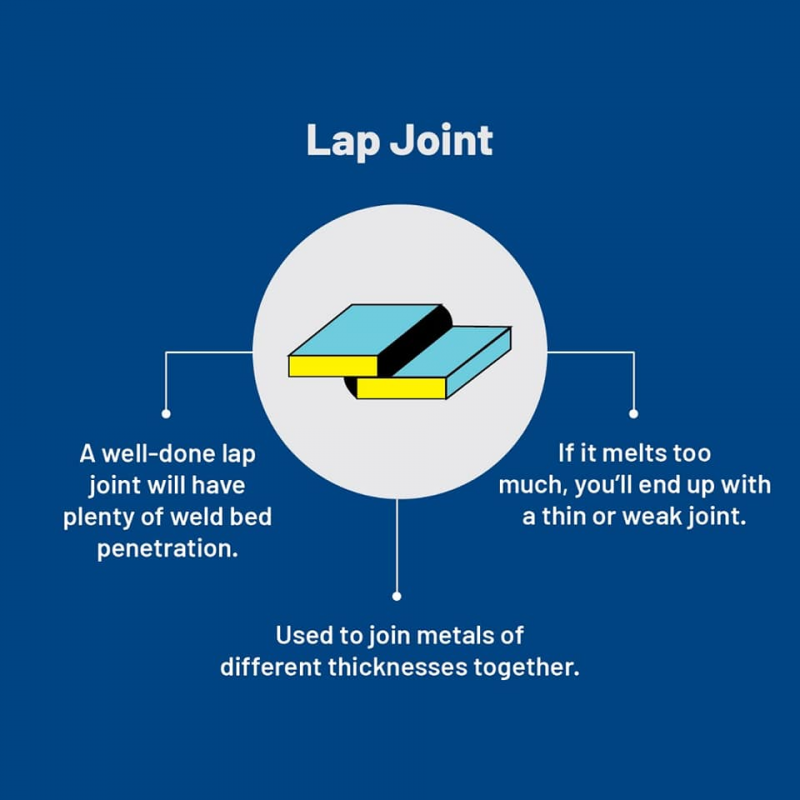

Lap Joint is the most commonly used to join metals of different thicknesses together. A well-done lap joint will have plenty of weld bed penetration. If it melts too much, you’ll end up with a thin or weak joint.

Edge Joint applied when joining parallel pieces together. It’s not a strong joint, but it is used mostly for sheet metal. It makes deeper penetration impossible and it works on flanging edges. To create this joint, you can use J-grooves, V-grooves, U-grooves, corner-flanges, bevel-groove, square-groove, or edge-flange welds.

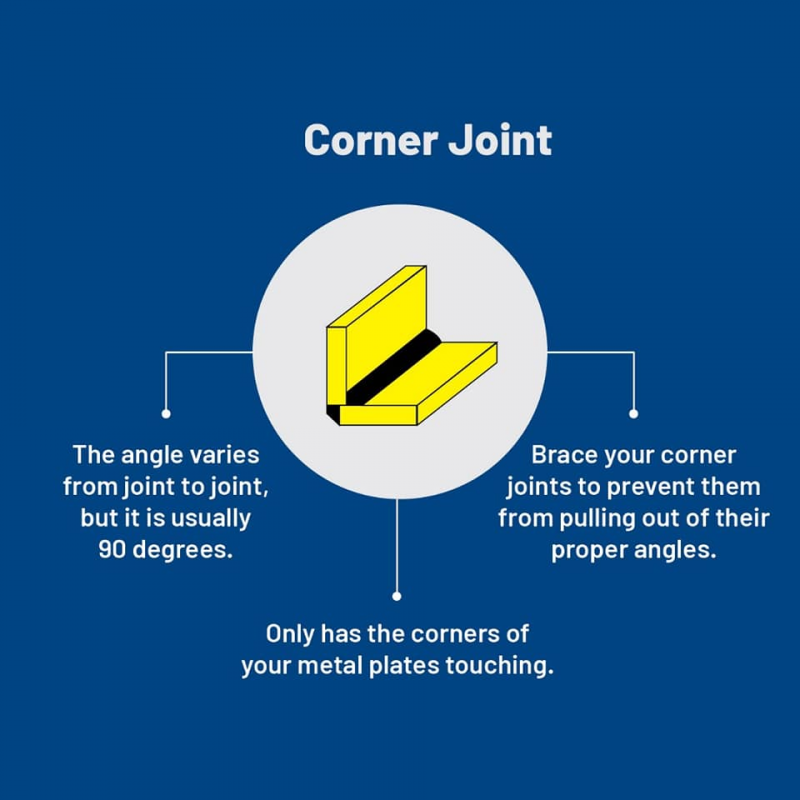

Corner Joint is on of the popular welds in the sheet metal industry. The angle varies from joint to joint, but it is usually 90 degrees. Only has the corners of your metal plates touching. Brace your corner joints to prevent them from pulling out of their proper angles. This is the most frequently used in the construction of boxes and box frames.

Leave A Comment

You must be logged in to post a comment.