Should you weld up or down? What power level should you use? TIG Welding can be challenging to a novice. Notwithstanding that practice makes perfect, keeping some tips up your sleeve would be greatly helpful. Here with the 7 Basic TIG Welding Tips, perfect for novice to sharpen your skills in producing high purity welds.

Use The Minimum Power:

Do not take it too lightly. Too much power can cause the weld to burn through. At least at a power setting that you can sustain to come up with a puddle technique that is enough to create a strong and solid weld.

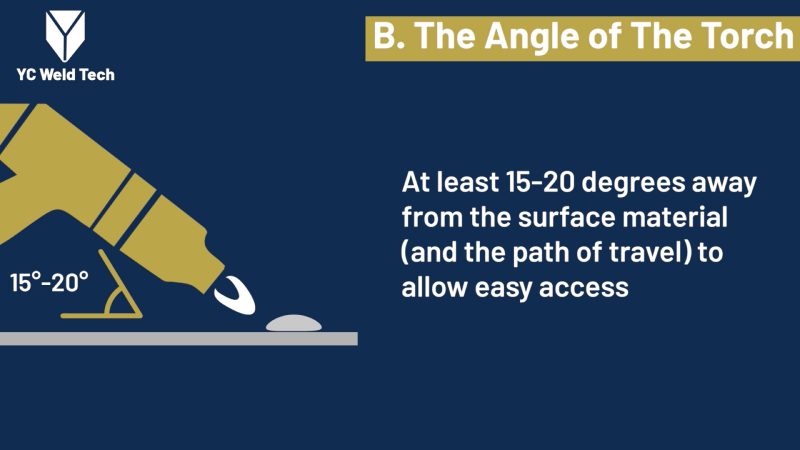

The Angle of The Torch:

At least 15-20 degrees away from the surface material (and the path of travel) to allow easy access of the filler material and to have increased visibility of the part to be welded. The angle matters.

Keep The Materials Clean:

Cleaning is important in welding because metals have to be clean to ensure a strong welding arc. For aluminum and stainless steel, recommended to use a delicate brush for each type of metal.

Don’t Melt The Filler Rod Directly:

The base metal is melted by the torch while the filler material is melted by the molten puddle. Avoid melting material directly as this will only result in a weak weld.

Wear Protective Gear:

Make it as a habit and it is compulsory to wear a respirator to protect your nose and mouth as Tungsten electrodes emit a low level of radiation. Practice TIG welding at a properly ventilated area to prevent the dust.

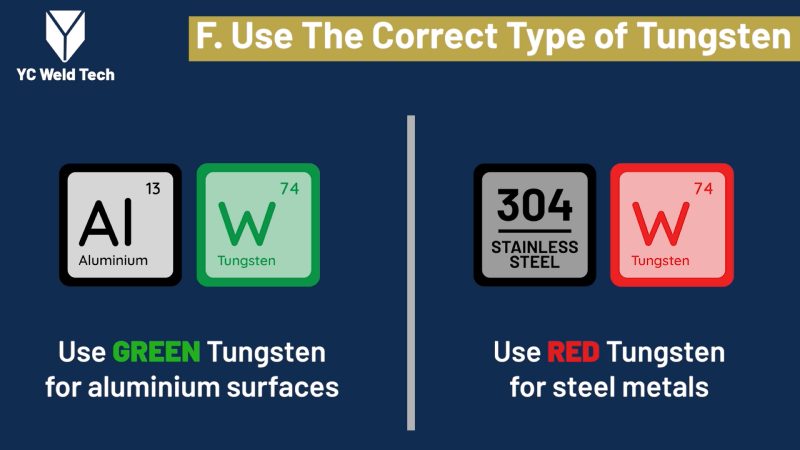

Use The Correct Type of Tungsten:

Use green tungsten as much as possible for aluminum surfaces. And use red tungsten for steel metals.

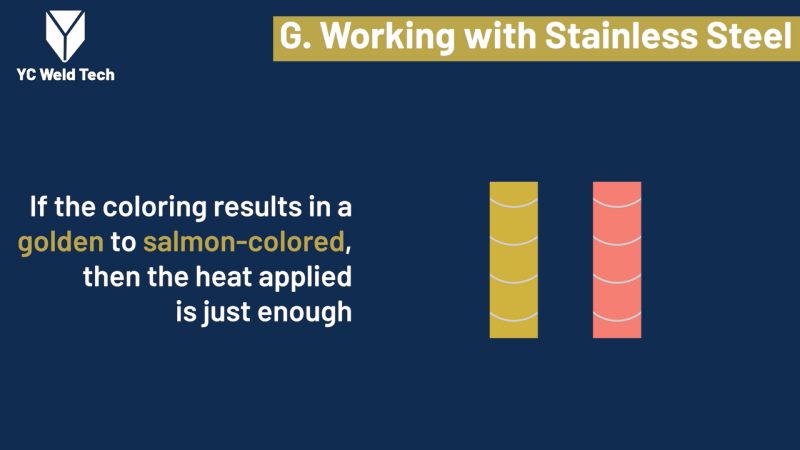

Working with Stainless Steel:

Be cautious when applying excessive heat when working with stainless steel by simply observing the color of the weld. If the coloring results in a golden to salmon-colored, then the heat applied is just enough.

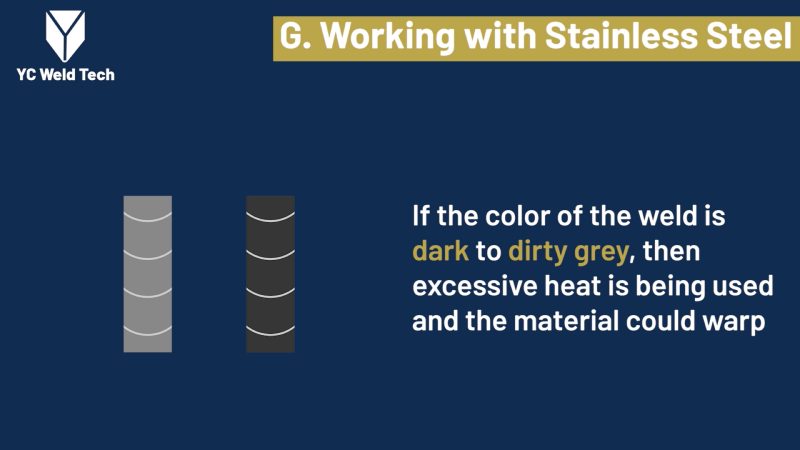

Working with Stainless Steel:

If the color of the weld is dark to dirty gray, then excessive heat is being used and the material could warp.

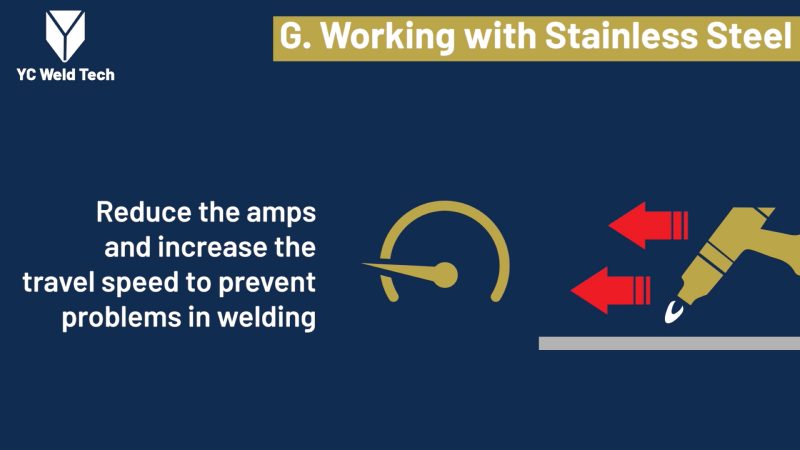

Working with Stainless Steel:

Reduce the amps and increase the travel speed to prevent problems in welding.

Working with Stainless Steel:

Reduce the thickness of the filler rod as it can be melted easily with moderate heat.

Leave A Comment

You must be logged in to post a comment.